Microbial Mites: An Enzyme War

Scientists propel research into a groundbreaking discovery — an organism found to break down plastic waste, holding a potential solution to a global problem.

In laboratories, scientists are able to break down and track specific evolutionary records in order to manipulate and select and modify the most promising strains.

Take a quick look at your hands, then the surface of your mask, the bottom of your shoe, or the cup of yogurt sitting on your desk. What do all of these have in common? They’re all breeding grounds for millions of bacteria. Now think of your body — the intestines wrapped around churning with foods you ate, maybe that same cup of yogurt and a chug of water from a crisp water bottle. Between these, the common denominator is plastic. Cumulatively, there are trillions of cells of bacteria, and a rivaling number of pieces of plastic. Together they each plague us with weighty issues like global warming and disease, making them a troublesome duo. Yet in some twist of the evolutionary tree, mother nature may have created the solution to put the two against each other. Scientists off the shores of a recycling facility in Sakai, Japan discovered a microbial mite, an organism holding the power to fend off growing depths of plastic dumps by eating it from the surface to the core.

To conceptualize the power of this mini warrior, think back to the last biology lesson you can remember, and paint the picture of a bacterial cell and its biological makeup. Bacteria are part of the natural world in the dome of microbes as a prokaryote, so they have no nucleus. The star of today’s show is Ideonella sakaiensis (I. Sakeinsis in short), from the Camomondacae family. This bacteria is gram-negative, meaning that it has excellent resilience to antibiotics. Each bacterium has a thin cell wall and high lipid content and can be found in moist oxygen-rich oils considering the aerobic qualities. I. Sakeinsis also has an aerobic rod-shaped flagellum or a tail-like structure attached to one end that provides motility. This structure allows the bacterium to float individually through substances, moving to its next supply of carbon-filled plastics. Now, the flagellum has propelled this bacteria species into the future through innovation and ecological advancement as the next inkling for a weapon against global warming.

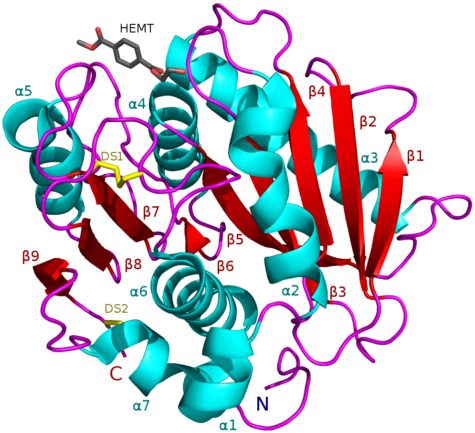

With all that covered, the truly astonishing quality of I. Sakeinsis is the ability to deconstruct polyethylene terephthalate (PET) into ethylene glycol and terephthalic acid using PETase and MHETase. Simply put, this magnificent microbe can deconstruct the structures found inside plastic using two enzymes to create two simple monomers. In a conversation with Dr. Lars Blank, an engineer and biologist at the RWTH Aachen University, he noted that the most interesting result is the exclusiveness of the enzyme, which allows for the “selective degradation in the presence of other molecules. This indeed allows the reuse of the monomers, with the company Carbios going for a 50.000 ton PET recycling plant, using the LCC enzyme.” Large companies like Carbios, and several other companies in the field of biochemistry, intend on genetically modifying bacteria to maneuver through several obstacles. With a combination of several enzymes, it may be possible to develop the remnants of the plastic degradation into future profitable production lines. Now I bet you’ve never thought of that water bottle on your desk becoming a flavoring for your cakes or cookies, but it may indeed become true along with a wide array of magical transformations.

As we all know, there are several types of plastics. From the nylon of umbrellas to containers to hollow pipes, around 7 categories of plastics are commonly used worldwide. The list goes as follows, Acrylic or Poly Methyl Methacrylate (PMMA), Polycarbonate (PC), Polyethylene (PE), Polypropylene (PP), Polyethylene Terephthalate (PETE or PET), Polyvinyl Chloride (PVC), and Acrylonitrile-Butadiene-Styrene (ABS). Each category is determined by the amorphous structure which determines physical properties. These properties determine opacity, strength, stability, and resistance to heat and chemicals. In this case, chemical resistance affects the ability of our microbial mite to deconstruct piece of plastic.

All plastics are constructed of chains of monomers, or particles, that are held together through molecular bonds. As mentioned before, I. Sakaiensis can deconstruct PET which is the fourth most produced type and is easily recyclable. It can be identified with the number 1 inside a recycling symbol. These identification codes not only help the separation of the plastic, but also dictate the lengthy recycling process. Heat, air, light, and water are the common culprits in the degradation of plastic polymers, but oxidation and chain scission can also instigate a reduction in plastic size or quantity.

In the actual degradation, the bacteria latch onto the surface of the plastic and secrete enzymes that split the esters, or chemical bonds, of the polymer chains. Some of the monomers in the results could be consumed by the bacteria, while others remain in the environment. I. Sakaesis secretes one particular enzyme called PET hydrolase, or PETase which can break down PET into an intermediate known as heterodimer. Then another enzyme named MHETase degrades the heterodimer into the final two remnants, terephthalic acid(TPA) and ethylene glycol (EG). This process continues until around 75% of the carbons in the plastic monomers are released into the environment. With the remnants of this cycle, scientists could theoretically convert plastics into vanillin — the synthetically produced compound that carries the scent and flavor of vanilla. So far, vanillin is known to be sourced from chemicals found in fossil fuels. However, the production and manipulation of safe plastic degradation point to the potential transformation of vanillin production in the food, cosmetic, pharmaceutical, cleaning, and herbicide industries, which are all growing rapidly.

I. Sakaiensis was particularly astonishing for its potential amiable qualities. Thus far, there are only a few bacteria and fungi known for the same characteristics, and no other organisms were known to be part of the recycling and bioremediation process. However, this potential turned out to be short-winded, and the aforementioned complications in the actual degradation process include the remnants which can be more toxic than the original plastic pollution. Along with limitations to PET plastics, scientists debate the content of the leftover plastic and most reported cases reveal that the degradation is incomplete and far too slow. In several cases, researches are led to believe that the bacteria does not induce any biochemical changes, but instead simply shreds it into microscopic bits.

To great dismay, safe use of I. Sakaiensis in the global market will most likely not come to fruition. While the selectivity of the enzyme present in the bacteria is indeed interesting, it’s too powerful in comparison with its slow speed. This means that “one might need two enzymes, and the microbe to facile,” as Blank mentions, to properly decompose each particle. In addition to this, as one can imagine, there are several quite difficult stages in the cultivation of the enzyme. The actual process is geared for temperatures in the range of 30°C, yet the glass transition of PET is above 70°C. Along with limitations in the environments of decomposition, many companies cite the cost to be incompatible with other technologies, like simple chemical reductions. The enzymes themselves also have disadvantages in reaching the PET structures, stemming from the availability of surface contact. In other types of plastics aside from PET, it can be increasingly difficult to break down monomers, if not impossible.

Unfortunately, research and trials have led scientists further from the idea of natural plastic degradation and into a deeper pit of questions and hypotheticals. Considering issues of environmental sustainability and potential non-eco-friendly toxin release, I. Sakeinsis has been set off for further investigation. Outside the laboratory, the introduction of the bacteria- even in its perfected form still poses a threat. With the knowledge that the bacteria will naturally evolve further to eat plastic, it may become practically impossible to tame it to only degrade what materials are ready for decomposition. While there are plenty of similar strains of bacteria stemming from Ideonella Sakaiensis, the native enzyme remains the prime contender for its malleability.

If it seems complicated already, there is yet another wrinkle to the situation. While fully sorted plastics may find tangible results in degradation, mixed plastics are more of a challenge. In the U.S., landfills are often used and many different types of plastics are dumped into the environment while recycling is either disincentivized because of cost, labor, or the general workload. As long as dumpling plastics into the environment champions the lower price tag, plastic degradation remains on hold. If that wasn’t enough, the proper laboratory procedures also equate to a large sum that is yet higher than the usage of synthetic degradation.

With that, Europe and China are tackling the challenge head-on with more bioplastic production. As the rapid growth in the global market and changes in research developments spur, researchers pave the way to smite these challenges, and the hopes of recycled plastic remain adjourned.

Now I bet you’ve never thought of that water bottle on your desk becoming a flavoring for your cakes or cookies, but it may indeed become true along with a wide array of magical transformations.

Eyenain Misgar is a Spotlight Editor for 'The Science Survey.' Eyenain finds the most appealing aspect of journalism to be the coverage and inspiration...